Business Model

Zespół Elektrociepłowni Wrocławskich KOGENERACJA SA consists of three production plants with a total electrical capacity of 365.7 MW and heating capacity of 1,080.4 MW. KOGENERACJA SA is a producer of network heat and electricity through cogeneration.

As a producer of heat for Wrocław and its surroundings, the Company satisfies the demand for heating, domestic hot water and technological heat and generates electricity as part of the national power system. Heat and electricity are produced by way of cogeneration, which ensures highly efficient average yearly production due to the most effective utilization of chemical energy of primary fuels in the entire energy sector. Network heat and electricity are primarily produced using hard coal and biomass.

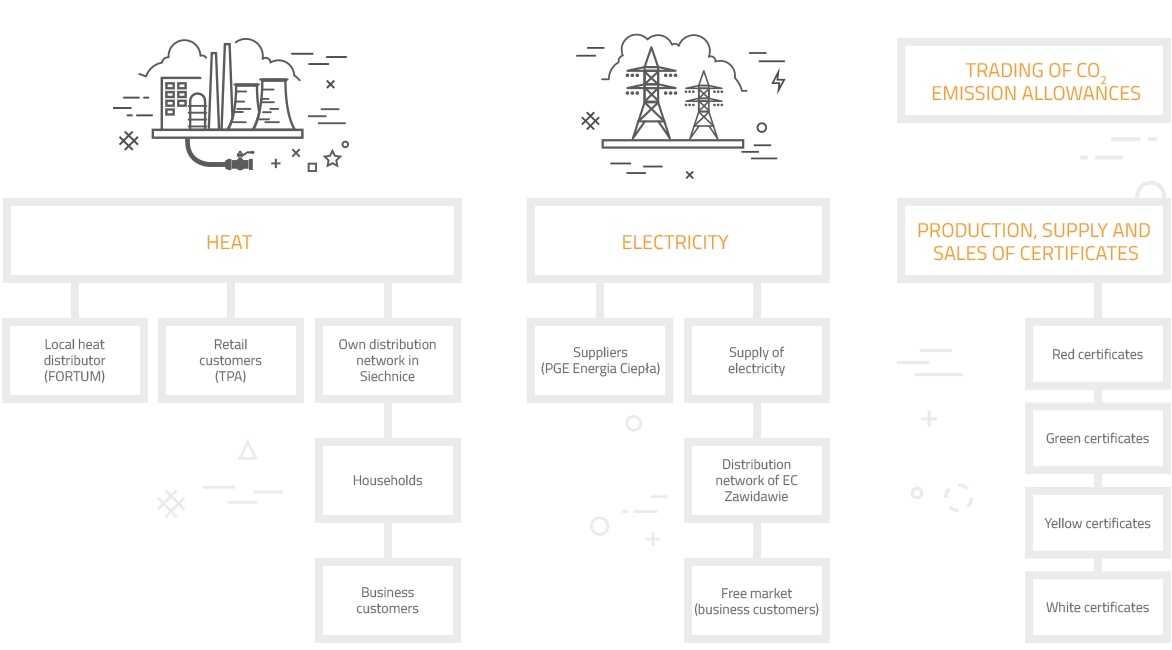

Chart: The business model of KOGENERACJA S.A.

EC Zielona Góra S.A. is a commercial enterprise producing heat and electricity in a combined system. The company produces electricity through cogeneration in the CC Gas Unit with an installed capacity of 198 MW. It owns a heating network and is a distributor of heat.

Production, sale and distribution of heat

Heat is the main product produced in the combined system at KOGENERACJA SA. It is sold to local customers (Wrocław, Siechnice) in the form of hot water. The price of heat is regulated (tariffs for heat are subject to approval by the President of the Energy Regulatory Authority (URE)). Heat is sold to Fortum Wrocław, a distributor company but also directly to retail customers. The company distributes heat through its own network in Siechnice.

EC Zielona Góra S.A. also produces heat in a combined system. It also owns a heating network and is a heat distributor. It is the only supplier of heat to the district heating system and of hot domestic water in Zielona Góra (Elektrociepłownia Zielona Góra S.A. is the owner of this system). The share of Elektrociepłownia Zielona Góra S.A. in the heat market in Zielona Góra amounts to 44%. The heating networks are 123.82 km long (including 75.19 km of pre-insulated lines). The company operates nine local gas boiler plants.

Generation and sale of electricity KOGENERACJA S.A. produces electricity in combination with heat at three generating units: EC Wrocław, EC Czechnica and EC Zawidawie, from which it is transmitted to distributors. Electricity is sold through the trading company PGE Energia Ciepła S.A.

Electricity generation and sales

KOGENERACJA S.A. produces electricity in combination with heat at three plants: EC Wrocław, EC Czechnica and EC Zawidawie, from where the generated heat and power are transmitted to distributors. Electricity is sold through the trading company PGE Energia Ciepła S.A.

Since August 2004, EC Zielona Góra S.A. has mainly produced electricity in the CC Gas Unit in a partial cogeneration process by using gas fuel (gas from local sources).

Generation and sale of certificates

KOGENERACJA S.A. obtains certificates of origin mainly from cogeneration (red and yellow certificates) and from co-firing of biomass (green certificates). EC Zielona Góra S.A. obtains certificates of origin from cogeneration (yellow certificates).

Certificates are traded through PGE Energia Ciepła S.A., a trading company. The companies are required to redeem certificates due to the sale of electricity to end users also through PGE Energia Ciepła S.A.

Trading in CO2 emission allowances

The Group purchases and sells CO2 emission allowances through PGE Energia Ciepła S.A. The companies independently redeem CO2 emission allowances in keeping with the actual emissions.

Group structure

KOGENERACJA Group includes the Parent Company KOGENERACJA S.A. with its registered office in Wrocław and one subsidiary Elektrociepłownia Zielona Góra S.A. with its registered office in Zielona Góra. KOGENERACJA S.A. has a 98.4% in its share capital and voting power.

Certified management systems

Each Group company has Integrated Management Systems, which include:

- Quality Management System compliant with the PN-EN ISO 9001:2015 standard,

- Environmental Management System, compliant with the requirements of the PN-EN ISO 14001: 2015 standard;

- Health and Safety Management System compliant with PN-N-18001:2004 and OHSAS 18001:2007 standards.

The above specified systems are subject to annual audits carried out by independent certification bodies.

Risk management

The Corporate Risk Management Procedure is in force in all Group companies. The Procedure lays down the terms of organization of the control activities which ensure proper risk management in the Group. Additional procedures in this area include: the Credit Risk Management Policy, the Policy of Managing Market Risk in Trading Activity and the Internal Audit Regulations.

The risk management system covers all the areas of operations of KOGENERACJA S.A., including its financial activities, and is operated in accordance with the principles in force. A Risk Map for the Company and for all Group companies is prepared and updated on an ongoing basis. Risks are identified in all operating areas, assessed and prioritized using the following 3 criteria: impact, likelihood and the control level. Where the risk is assessed as high, an owner of the risk is appointed and a mitigation plan is drawn up. For the main risks a periodic assessment of the risk mitigation plans is carried out. Risk Controllers and Directors are involved in the risk assessment process. Under an executed SLA, the Risk Management and Security Oversight Directorate of PGE Energia Ciepła S.A. coordinates the process of reporting the Company’s risks to the owner.

The management boards of all Group companies independently monitor financial, legal, environmental, operational, market, PR and media and investment risks. Their risk maps are presented at Supervisory Board meetings.

In the process of identifying risks and analyzing their likelihood and impact, the following key non-financial risks were selected:

Social risks

- Insufficient employee skills – the potential of the current technical employees in relation to the Ready for the Future reference model; the risk of a failure to execute the Detailed Training Schedules.

Ongoing activities:

- Training for technical employees, in accordance with Individual Training Plans (IPS) and Detailed Training Schedules (SHS). Adapting the organization of the Technical Directorate to the reference model by 2020.

- Providing training space for the implementation of SHS in accordance with the Training Plan.

- Recruiting new employees in accordance with the competency profile.

- Risk of an accident at work as a result of inappropriate behavior on the part of a Company employee or a contractor.

Ongoing activities:

- Occupational Health & safety improvement plans

- Site visits by the management

- Cooperation with subcontractors in the area of occupational safety

- Exchange of good practices within the Occupational Health & Safety network

- Additional upskilling training courses

- Dodatkowe szkolenia rozwijające kompetencje

- Overview of the operation of the PnP system

- Training events for employees and subcontractors at the “Zero Accidents Centre”

Environmental risks

Failure to meet the requirements of the Industrial Emissions Directive at EC Czechnica. As of 1 January 2016, stricter emission standards for coal combustion have been in force, namely, for SO2 – 250mg/Nm3, for NOx – 200mg/Nm3 and for dust – 25mg/Nm3. Until the end of 2022 EC Czechnica can conduct its operations pursuant to granted derogations. After the deadline, it will be necessary to launch new units that meet stricter environmental standards.

Planned activities:

Making a decision about the construction of a new plant at EC Czechnica after 2022.

Key non-financial performance indicators reflecting the operations of the KOGENERACJA S.A. Group

In the process of managing operations and making decisions, the following non-financial indicators are particularly taken into account:

- Total number of accidents related to the employees’ work

- Total number of accidents related to contractors’ work

- Raw materials consumption

- Air emissions

- Average number of training hours per year and training costs

- Number of employees by type of employment and employment contract, broken down by gender (persons).